-

Table of Contents

“Smooth Solutions: Banish Air Bubbles for Flawless Resin Creations!”

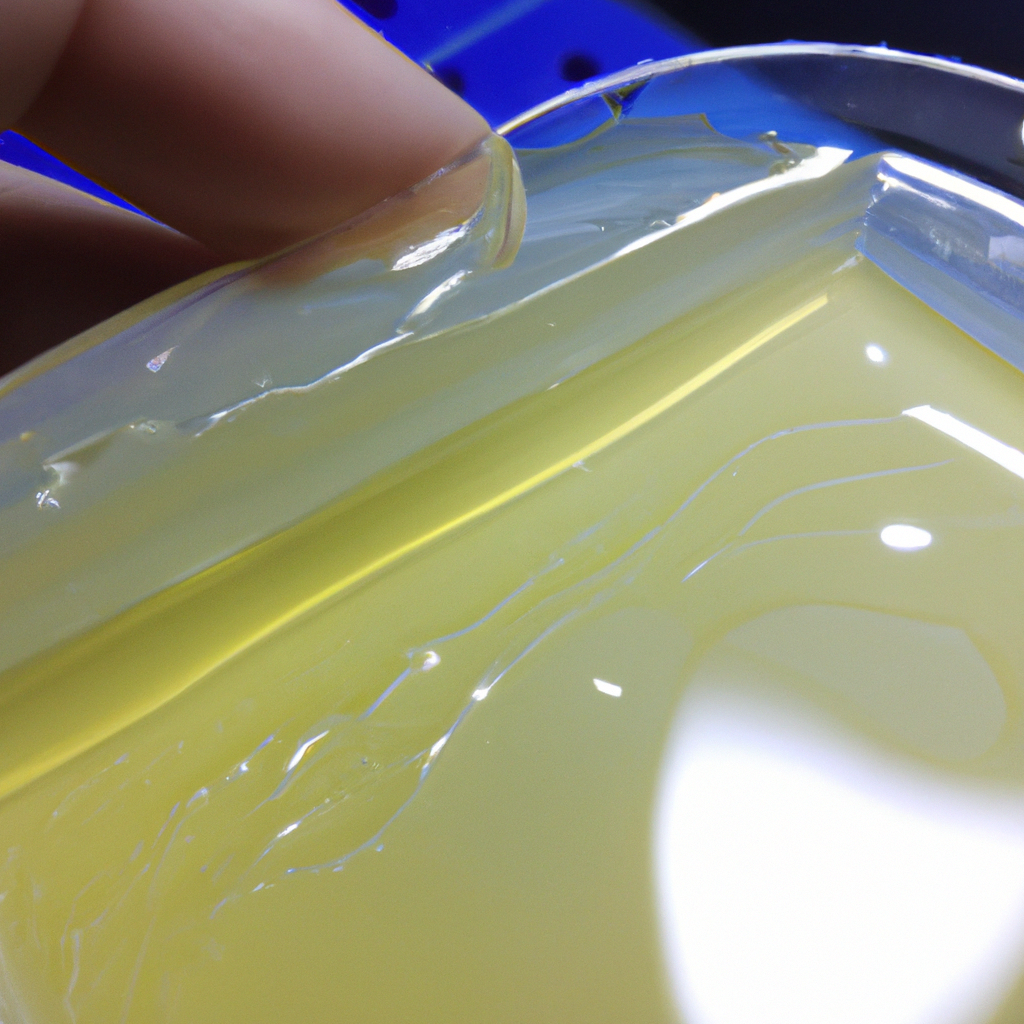

Dealing with air bubbles in resin projects is a common challenge that can affect the final appearance and integrity of the finished product. Air bubbles can form during the mixing and pouring processes, leading to imperfections that may compromise the aesthetic and structural quality of the resin piece. Understanding the causes of air bubbles and implementing effective techniques for their prevention and removal is essential for achieving a smooth, professional-looking result. This guide will explore various methods to minimize air bubbles, including proper mixing techniques, the use of heat sources, and post-pour treatments, ensuring a successful resin project.

Techniques for Preventing Air Bubbles in Resin Casting

When embarking on resin casting projects, one of the most common challenges faced by artisans and hobbyists alike is the formation of air bubbles. These unsightly imperfections can mar the surface of a finished piece, detracting from its overall aesthetic appeal. Therefore, understanding techniques for preventing air bubbles is essential for achieving a flawless result.

To begin with, one of the most effective methods for minimizing air bubbles is to ensure that the resin and hardener are mixed thoroughly yet gently. When combining these two components, it is crucial to avoid vigorous stirring, as this can introduce air into the mixture. Instead, a slow and deliberate mixing technique should be employed, allowing the materials to blend without creating excessive agitation. Additionally, using a mixing stick with a flat edge can help scrape the sides of the container, ensuring that all components are incorporated without trapping air.

Moreover, the temperature of the workspace plays a significant role in bubble formation. Warmer temperatures can reduce the viscosity of the resin, allowing air bubbles to rise more easily to the surface. Therefore, it is advisable to work in a controlled environment where the temperature is maintained between 70°F and 80°F (21°C to 27°C). Furthermore, preheating the resin and hardener slightly before mixing can also help reduce viscosity, thereby facilitating the escape of trapped air.

In addition to temperature control, utilizing a vacuum chamber is another highly effective technique for preventing air bubbles. By placing the mixed resin in a vacuum chamber, any trapped air is drawn out, resulting in a bubble-free mixture. This method is particularly beneficial for projects that involve intricate molds or when working with materials that are prone to trapping air. While investing in a vacuum chamber may require a higher initial cost, the benefits it provides in terms of quality and finish can be well worth the expense.

Another practical approach involves the use of a heat gun or torch after pouring the resin into the mold. By gently applying heat to the surface of the resin, any remaining air bubbles can be encouraged to rise and pop. It is important to exercise caution during this process, as excessive heat can cause the resin to cure too quickly or even scorch. Therefore, maintaining a safe distance and using short bursts of heat will yield the best results.

Furthermore, selecting the right type of resin can also influence the likelihood of bubble formation. Some resins are specifically formulated to minimize bubbles, offering a more user-friendly experience for beginners and seasoned crafters alike. Researching and choosing a high-quality resin that suits the specific requirements of a project can significantly reduce the chances of encountering air bubbles.

Lastly, it is essential to consider the pouring technique itself. Pouring the resin slowly and from a height can help minimize the introduction of air. Additionally, pouring in layers can allow for better control over the process, as each layer can be monitored for bubbles before adding the next. This method not only enhances the overall appearance of the final piece but also provides an opportunity to address any imperfections as they arise.

In conclusion, preventing air bubbles in resin casting requires a combination of careful mixing, environmental control, and strategic techniques. By implementing these methods, artisans can enhance the quality of their projects, resulting in stunning, bubble-free finishes that showcase their craftsmanship.

Effective Methods for Removing Air Bubbles from Cured Resin

Dealing with air bubbles in resin projects can be a frustrating experience for both novice and experienced crafters alike. Once the resin has cured, these bubbles can become permanent fixtures, detracting from the overall aesthetic and integrity of the finished piece. However, there are effective methods for removing air bubbles from cured resin that can help restore the quality of your work. Understanding these techniques is essential for achieving a flawless finish.

One of the most straightforward methods for addressing air bubbles in cured resin is the use of heat. A heat gun or a torch can be employed to gently warm the surface of the resin. As the resin heats up, it becomes more fluid, allowing trapped air bubbles to rise to the surface and pop. It is crucial to maintain a safe distance between the heat source and the resin to avoid scorching or damaging the material. A consistent, sweeping motion will help distribute the heat evenly, ensuring that the resin does not overheat in any one area. This method is particularly effective for small bubbles and can be done shortly after the resin has been poured.

In addition to heat, another effective technique involves the use of a vacuum chamber. This method is particularly beneficial for larger projects or when working with thicker layers of resin. By placing the mixed resin in a vacuum chamber before pouring, the atmospheric pressure is reduced, allowing air bubbles to escape. This process can significantly minimize the number of bubbles that form during curing. However, it requires specialized equipment and may not be feasible for all crafters. For those who have access to a vacuum chamber, this method can yield impressive results, ensuring a clear and smooth finish.

Moreover, incorporating additives can also help mitigate the formation of air bubbles in resin. Certain products, such as silicone oil or specific types of surfactants, can be mixed into the resin before pouring. These additives can reduce surface tension, allowing bubbles to escape more easily. However, it is essential to use these additives sparingly and to conduct tests beforehand, as they can alter the properties of the resin if not used correctly. By experimenting with different formulations, crafters can find the right balance that works for their specific projects.

Another practical approach is to pour the resin slowly and steadily. Rapid pouring can introduce air into the mixture, leading to an increased likelihood of bubbles forming. By pouring the resin in a thin stream and at a controlled pace, crafters can minimize the introduction of air. Additionally, pouring from a height can create turbulence, which can also trap air. Therefore, keeping the pouring height low and steady can significantly reduce bubble formation.

Finally, patience plays a crucial role in dealing with air bubbles in resin projects. Allowing the resin to sit for a few minutes after mixing can give bubbles time to rise to the surface before pouring. This simple step can make a noticeable difference in the final outcome. By combining these methods—heat application, vacuum chambers, additives, careful pouring, and patience—crafters can effectively manage air bubbles in their resin projects. Ultimately, understanding and implementing these techniques will lead to a more polished and professional finish, enhancing the overall quality of the work.

Best Practices for Mixing Resin to Minimize Air Inclusion

When embarking on resin projects, one of the most common challenges faced by artisans and hobbyists alike is the presence of air bubbles. These unwanted inclusions can mar the aesthetic quality of a finished piece, leading to frustration and disappointment. To mitigate this issue, it is essential to adopt best practices for mixing resin, which can significantly minimize air inclusion and enhance the overall outcome of the project.

To begin with, selecting the right resin is crucial. Different types of resin have varying viscosities and curing properties, which can influence the likelihood of air bubbles forming during the mixing process. For instance, low-viscosity resins tend to trap fewer air bubbles compared to their high-viscosity counterparts. Therefore, it is advisable to choose a resin specifically designed for the intended application, as this can set the foundation for a successful project.

Once the appropriate resin has been selected, the next step involves careful measurement of the components. Accurate ratios of resin to hardener are vital, as improper mixing can lead to incomplete curing and increased bubble formation. Utilizing a digital scale for precise measurements is recommended, as this ensures consistency and reliability in the mixing process. Furthermore, it is beneficial to mix smaller batches, as this allows for better control over the mixing environment and reduces the risk of introducing air.

As the mixing process begins, it is important to adopt a gentle approach. Stirring too vigorously can introduce air into the mixture, leading to the formation of bubbles. Instead, a slow and deliberate mixing technique should be employed, allowing the components to blend without agitating the mixture excessively. Additionally, using a flat stir stick or a silicone spatula can help scrape the sides and bottom of the mixing container, ensuring that all material is thoroughly combined while minimizing the introduction of air.

Moreover, the choice of mixing container plays a significant role in reducing air bubbles. Clear, disposable cups are often preferred, as they allow for easy visibility of the mixture and help identify any bubbles that may form during the process. It is advisable to avoid using containers with textured surfaces, as these can trap air and complicate the mixing process. Instead, opting for smooth, clean containers will facilitate a more effective blending of the resin and hardener.

After mixing, allowing the resin to sit for a few minutes can further aid in bubble reduction. During this resting period, any trapped air bubbles will naturally rise to the surface, where they can be easily removed. Utilizing a heat gun or a torch can also be effective in eliminating surface bubbles. By gently passing the heat source over the resin, the bubbles will expand and pop, resulting in a smoother finish.

In conclusion, minimizing air inclusion in resin projects requires a combination of careful selection, precise measurement, gentle mixing techniques, and appropriate tools. By adhering to these best practices, artisans can significantly reduce the occurrence of air bubbles, leading to a more polished and professional final product. Ultimately, the attention to detail in the mixing process not only enhances the aesthetic appeal of the resin piece but also contributes to the overall satisfaction of the creator. With these strategies in mind, anyone can navigate the challenges of working with resin and achieve stunning results.

Q&A

1. **Question:** What causes air bubbles in resin projects?

**Answer:** Air bubbles in resin projects are typically caused by mixing the resin too vigorously, introducing air into the mixture, or by using materials that release trapped air when heated.

2. **Question:** How can I prevent air bubbles from forming in my resin?

**Answer:** To prevent air bubbles, mix the resin slowly and gently, use a heat gun or torch to pop bubbles after pouring, and consider using a vacuum chamber to degas the resin before use.

3. **Question:** What should I do if I notice air bubbles after the resin has cured?

**Answer:** If air bubbles are present after curing, you can sand the surface to remove them and then apply a new layer of resin to fill in the gaps, or use a clear epoxy to coat the surface.In conclusion, effectively dealing with air bubbles in resin projects requires a combination of proper mixing techniques, the use of heat sources, and the application of vacuum or pressure methods. By taking preventive measures such as mixing slowly, using a degassing chamber, and allowing the resin to rest before pouring, one can significantly reduce the occurrence of air bubbles. Additionally, employing techniques like using a heat gun or torch to pop bubbles on the surface can enhance the final appearance of the project. Ultimately, attention to detail and patience are key to achieving a smooth, bubble-free finish in resin work.