-

Table of Contents

“Resin Shrinkage: Understanding the Causes, Mastering the Solutions.”

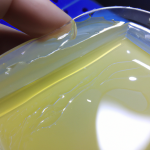

Resin shrinkage is a common phenomenon observed in various applications, particularly in the fields of manufacturing, construction, and art. It occurs when resin materials, such as epoxy or polyester, undergo a reduction in volume as they cure or harden. This shrinkage can lead to defects such as warping, cracking, or poor adhesion, ultimately affecting the integrity and aesthetics of the final product. The primary causes of resin shrinkage include the chemical composition of the resin, the curing process, temperature fluctuations, and the presence of additives. To mitigate these issues, several solutions can be implemented, including selecting low-shrinkage formulations, optimizing curing conditions, and employing techniques such as vacuum degassing or the use of fillers. Understanding the causes and solutions to resin shrinkage is essential for achieving high-quality results in resin-based projects.

Causes of Resin Shrinkage in Casting Processes

Resin shrinkage is a common phenomenon encountered in casting processes, and understanding its causes is essential for achieving optimal results in various applications. One of the primary factors contributing to resin shrinkage is the chemical composition of the resin itself. Different types of resins, such as epoxy, polyester, and polyurethane, exhibit varying degrees of shrinkage due to their unique molecular structures and curing mechanisms. For instance, epoxy resins typically experience less shrinkage compared to polyester resins, which can expand and contract more significantly during the curing process. This inherent characteristic of the resin plays a crucial role in determining the final dimensions of the cast object.

In addition to the resin type, the curing process significantly influences shrinkage. The temperature and humidity conditions during curing can lead to variations in the resin’s behavior. Elevated temperatures often accelerate the curing reaction, which can result in increased shrinkage as the resin transitions from a liquid to a solid state. Conversely, low temperatures may slow down the curing process, potentially leading to incomplete polymerization and, consequently, a different kind of dimensional instability. Furthermore, humidity can affect the moisture content in the resin, which may also contribute to shrinkage. Therefore, maintaining controlled environmental conditions during the curing process is vital for minimizing shrinkage.

Another critical factor is the presence of fillers and additives within the resin formulation. Fillers are often incorporated to enhance specific properties, such as strength, weight, or thermal resistance. However, the type and amount of filler used can significantly impact the shrinkage behavior of the resin. For example, certain fillers may absorb moisture or expand during the curing process, which can counteract the shrinkage of the resin itself. On the other hand, some fillers may not bond well with the resin, leading to voids or inconsistencies that exacerbate shrinkage issues. Consequently, careful selection and optimization of fillers are necessary to achieve a balanced formulation that minimizes shrinkage while maintaining desired performance characteristics.

Moreover, the geometry of the mold and the casting process itself can also contribute to resin shrinkage. Complex mold designs with intricate features may lead to uneven cooling and curing rates, resulting in differential shrinkage across the cast object. This phenomenon can create internal stresses and warping, further complicating the dimensional accuracy of the final product. To mitigate these issues, it is essential to design molds that promote uniform heat distribution and allow for adequate venting of gases generated during the curing process. Additionally, employing techniques such as vacuum casting or pressure casting can help reduce air entrapment and improve the overall quality of the cast.

Lastly, the timing of demolding plays a significant role in managing resin shrinkage. Removing the cast object from the mold too early can lead to deformation and surface imperfections, while waiting too long may result in difficulties in demolding due to increased adhesion between the resin and the mold surface. Therefore, establishing optimal demolding times based on the specific resin formulation and environmental conditions is crucial for minimizing shrinkage-related issues.

In conclusion, resin shrinkage in casting processes is influenced by a multitude of factors, including the chemical composition of the resin, curing conditions, the presence of fillers, mold geometry, and demolding timing. By understanding these causes and implementing appropriate solutions, manufacturers can significantly reduce shrinkage and enhance the quality and precision of their cast products.

Effective Solutions to Minimize Resin Shrinkage

Resin shrinkage is a common challenge faced by manufacturers and artisans alike, particularly in the fields of casting and molding. Understanding the causes of this phenomenon is crucial, but equally important is identifying effective solutions to minimize its impact. By implementing specific strategies, one can significantly reduce the occurrence of shrinkage, thereby enhancing the quality and integrity of the final product.

One of the primary methods to mitigate resin shrinkage is to carefully select the type of resin used in the application. Different resins exhibit varying shrinkage rates, and opting for low-shrinkage formulations can lead to more favorable outcomes. For instance, epoxy resins are known for their relatively low shrinkage compared to polyester resins. By choosing a resin specifically designed to minimize shrinkage, manufacturers can lay a solid foundation for successful casting.

In addition to selecting the appropriate resin, controlling the temperature during the curing process is vital. Temperature fluctuations can exacerbate shrinkage, as resins tend to expand when heated and contract upon cooling. Therefore, maintaining a consistent temperature throughout the curing phase is essential. Utilizing temperature-controlled environments or heating mats can help achieve this stability, ensuring that the resin cures evenly and reduces the likelihood of shrinkage.

Moreover, the use of fillers and additives can also play a significant role in minimizing shrinkage. Incorporating materials such as microballoons or silica can help to reduce the overall volume of resin required, thereby decreasing the potential for shrinkage. These fillers not only enhance the physical properties of the resin but also contribute to a more stable curing process. However, it is crucial to strike a balance, as excessive filler can compromise the resin’s strength and clarity.

Another effective solution involves optimizing the mold design. A well-designed mold can facilitate the proper flow of resin and minimize trapped air, which can lead to uneven curing and subsequent shrinkage. Implementing features such as vents and risers can help to ensure that air is expelled during the pouring process, allowing for a more uniform distribution of resin. Additionally, using molds made from materials that have low thermal conductivity can help maintain a consistent temperature, further reducing the risk of shrinkage.

Furthermore, employing a slow curing process can also be beneficial. Rapid curing can lead to increased internal stresses within the resin, resulting in greater shrinkage. By allowing the resin to cure slowly, one can minimize these stresses and promote a more stable final product. This approach may require patience, but the long-term benefits in terms of quality and durability are often worth the wait.

Lastly, conducting thorough testing and quality control throughout the production process is essential. By regularly monitoring the properties of the resin and the conditions under which it is cured, manufacturers can identify potential issues before they escalate. This proactive approach not only helps in minimizing shrinkage but also enhances overall product reliability.

In conclusion, while resin shrinkage poses significant challenges, a variety of effective solutions exist to mitigate its effects. By selecting the right resin, controlling curing temperatures, utilizing fillers, optimizing mold designs, allowing for slow curing, and implementing rigorous quality control measures, manufacturers can significantly reduce shrinkage. These strategies not only improve the quality of the final product but also enhance the efficiency of the production process, ultimately leading to greater customer satisfaction and business success.

The Impact of Temperature on Resin Shrinkage Rates

Resin shrinkage is a critical factor that affects the quality and performance of resin-based products, particularly in industries such as manufacturing, construction, and art. One of the most significant influences on resin shrinkage rates is temperature, which can alter the physical properties of the resin during the curing process. Understanding how temperature impacts resin shrinkage is essential for achieving optimal results in any application involving resin.

To begin with, it is important to recognize that resins are typically composed of polymers that undergo a chemical reaction when cured. This reaction is exothermic, meaning it generates heat. As the temperature rises during the curing process, the viscosity of the resin decreases, allowing it to flow more easily into molds or fill voids. However, this increase in temperature can also lead to a higher rate of shrinkage. When the resin cools after curing, it contracts, and this contraction can be exacerbated by elevated temperatures during the initial stages of curing. Consequently, if the temperature is not carefully controlled, the final product may exhibit warping, cracking, or other defects due to uneven shrinkage.

Moreover, the type of resin used can also influence how temperature affects shrinkage rates. For instance, epoxy resins tend to have lower shrinkage rates compared to polyester resins. However, both types can experience significant changes in shrinkage behavior when subjected to varying temperatures. In general, higher temperatures can accelerate the curing process, leading to a rapid increase in shrinkage. Conversely, lower temperatures may slow down the curing process, allowing for a more gradual shrinkage that can be easier to manage. Therefore, it is crucial to select the appropriate resin type based on the specific temperature conditions of the application.

In addition to the type of resin, the ambient temperature during the curing process plays a vital role in determining shrinkage rates. For example, if the curing environment is too cold, the resin may not cure properly, resulting in incomplete polymerization and increased shrinkage. On the other hand, excessively high temperatures can lead to a phenomenon known as thermal runaway, where the heat generated during curing causes the resin to cure too quickly, leading to significant shrinkage and potential defects. Thus, maintaining an optimal temperature range is essential for minimizing shrinkage and ensuring the integrity of the final product.

To mitigate the effects of temperature on resin shrinkage, several strategies can be employed. First, it is advisable to conduct thorough testing to determine the ideal curing temperature for the specific resin being used. This testing can help identify the temperature range that minimizes shrinkage while ensuring complete curing. Additionally, using temperature-controlled environments, such as heated or cooled curing chambers, can help maintain consistent temperatures throughout the curing process. Furthermore, incorporating additives or fillers that are designed to reduce shrinkage can also be beneficial. These materials can help absorb some of the stresses associated with temperature fluctuations, leading to a more stable final product.

In conclusion, temperature significantly impacts resin shrinkage rates, influencing both the curing process and the final properties of the resin. By understanding the relationship between temperature and shrinkage, manufacturers and artisans can take proactive measures to control these variables, ultimately leading to higher-quality resin products. Through careful selection of resin types, monitoring of ambient conditions, and implementation of effective strategies, it is possible to minimize the adverse effects of temperature on resin shrinkage, ensuring successful outcomes in various applications.

Q&A

1. **What causes resin shrinkage during curing?**

Resin shrinkage during curing is primarily caused by the exothermic reaction that occurs as the resin hardens, leading to a reduction in volume. Additionally, the chemical structure of the resin can change, resulting in further shrinkage.

2. **How can resin shrinkage be minimized?**

To minimize resin shrinkage, use low-shrinkage formulations or additives specifically designed to reduce shrinkage. Maintaining optimal curing temperatures and using proper mixing techniques can also help.

3. **What are the effects of resin shrinkage on finished products?**

Resin shrinkage can lead to warping, cracking, or poor adhesion in finished products, compromising their structural integrity and aesthetic appearance.Resin shrinkage is primarily caused by the cooling and curing processes of the material, which can lead to dimensional changes and defects in the final product. Factors such as the type of resin, the presence of fillers, and environmental conditions during curing can exacerbate shrinkage. Solutions to mitigate resin shrinkage include optimizing the formulation by selecting low-shrinkage resins, controlling the curing temperature and time, using additives that reduce shrinkage, and employing techniques such as post-curing or reinforcement with fibers. By addressing these factors, manufacturers can improve the dimensional stability and overall quality of resin-based products.