-

Table of Contents

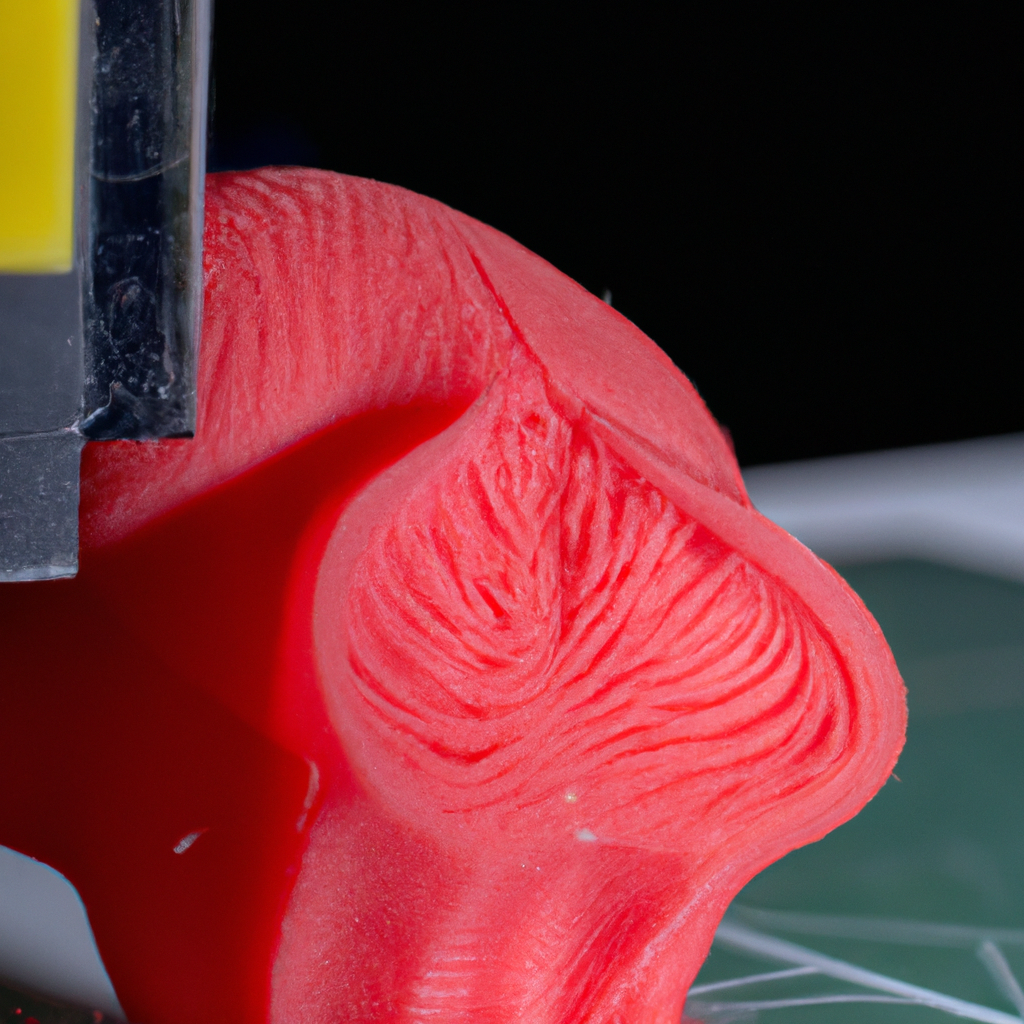

“Transforming Ideas into Reality: Precision 3D Printed Masters for Flawless Resin Molding.”

Using 3D printed masters in resin molding has revolutionized the manufacturing and prototyping processes across various industries. This innovative technique combines the precision of 3D printing with the versatility of resin casting, allowing for the creation of intricate and detailed molds that can produce high-quality replicas. By utilizing 3D printed masters, manufacturers can significantly reduce lead times, lower costs, and enhance design flexibility. This method is particularly advantageous for small production runs, custom parts, and complex geometries that traditional molding techniques may struggle to achieve. As technology continues to advance, the integration of 3D printing in resin molding is set to transform how products are designed and produced, offering new possibilities for creativity and efficiency.

Advantages of 3D Printed Masters in Resin Molding

The advent of 3D printing technology has revolutionized various industries, and one of its most significant applications is in the realm of resin molding. Utilizing 3D printed masters in the resin molding process offers a multitude of advantages that enhance both efficiency and quality. To begin with, the precision and accuracy of 3D printing allow for the creation of highly detailed masters that can capture intricate designs and features. This level of detail is often difficult to achieve with traditional methods, which can lead to discrepancies in the final product. By employing 3D printed masters, manufacturers can ensure that the molds reflect the exact specifications of the intended design, thereby reducing the likelihood of errors during production.

Moreover, the speed at which 3D printed masters can be produced is another compelling advantage. Traditional mold-making processes can be time-consuming, often requiring extensive manual labor and multiple iterations to achieve the desired outcome. In contrast, 3D printing streamlines this process significantly. Once a digital model is finalized, the master can be printed in a matter of hours, allowing for rapid prototyping and quicker turnaround times. This efficiency not only accelerates the development cycle but also enables businesses to respond swiftly to market demands, thereby gaining a competitive edge.

In addition to speed and precision, the cost-effectiveness of using 3D printed masters cannot be overlooked. Traditional mold-making techniques often involve substantial material waste and labor costs, particularly when creating complex shapes. Conversely, 3D printing minimizes waste by using only the necessary amount of material to create the master. Furthermore, the reduction in labor costs associated with manual mold-making processes contributes to overall savings. As a result, businesses can allocate resources more effectively, investing in other areas of production or innovation.

Another noteworthy benefit of 3D printed masters is their versatility. The technology allows for the easy modification of designs, enabling manufacturers to make adjustments quickly and efficiently. If a design change is required, the digital model can be altered, and a new master can be printed without the need for extensive retooling or additional costs. This adaptability is particularly advantageous in industries where consumer preferences are constantly evolving, as it allows companies to stay relevant and meet changing demands without significant delays.

Furthermore, the use of 3D printed masters can enhance the overall quality of the final resin products. The smooth surfaces and intricate details achieved through 3D printing translate into superior mold quality, which in turn results in better surface finishes and more accurate reproductions of the original design. This improvement in quality can lead to higher customer satisfaction and increased brand loyalty, as consumers are more likely to appreciate products that exhibit exceptional craftsmanship.

Lastly, the environmental impact of using 3D printed masters in resin molding is an important consideration. As sustainability becomes a growing concern across industries, the reduced material waste and energy consumption associated with 3D printing present a more eco-friendly alternative to traditional methods. By adopting this technology, companies can not only improve their operational efficiency but also contribute to a more sustainable future.

In conclusion, the advantages of using 3D printed masters in resin molding are manifold, encompassing precision, speed, cost-effectiveness, versatility, quality enhancement, and environmental sustainability. As the technology continues to evolve, it is likely that its integration into manufacturing processes will become increasingly prevalent, further transforming the landscape of production and design.

Best Practices for Creating 3D Printed Masters

The advent of 3D printing technology has revolutionized various industries, particularly in the realm of manufacturing and prototyping. One of the most significant applications of 3D printing is the creation of masters for resin molding. This process allows for the efficient production of high-quality parts with intricate details. However, to achieve optimal results, it is essential to adhere to best practices when creating 3D printed masters.

To begin with, selecting the appropriate 3D printing technology is crucial. Different methods, such as Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS), offer varying levels of precision and surface finish. For resin molding, SLA is often preferred due to its ability to produce highly detailed and smooth surfaces. This is particularly important because the quality of the master directly influences the final product’s appearance and functionality. Therefore, understanding the specific requirements of the project will guide the choice of printing technology.

Once the printing technology is selected, the next step involves designing the master model. It is vital to consider the geometry of the part, as complex shapes may pose challenges during the molding process. Incorporating draft angles into the design can facilitate easier removal of the molded part from the mold, thereby reducing the risk of damage. Additionally, ensuring that the model is watertight and free of errors is essential, as any imperfections can lead to defects in the final mold. Utilizing software tools for checking and repairing 3D models can significantly enhance the quality of the master.

Furthermore, optimizing the print settings is another critical aspect of creating effective 3D printed masters. Parameters such as layer height, print speed, and infill density should be carefully adjusted based on the desired level of detail and strength. A finer layer height can yield a smoother surface finish, which is particularly beneficial for aesthetic applications. However, it is important to balance this with print time and material usage, as excessively fine settings may lead to longer production times and increased costs.

In addition to print settings, post-processing techniques play a significant role in enhancing the quality of the 3D printed master. After printing, the model may require cleaning to remove any residual support structures or uncured resin. This step is crucial, as leftover materials can adversely affect the molding process. Following cleaning, sanding or polishing the surface can further improve the finish, ensuring that the final mold captures all the intricate details of the master. Applying a release agent to the master before molding can also facilitate easier demolding and prolong the life of the mold.

Moreover, it is essential to consider the material used for 3D printing the master. Different materials exhibit varying properties, such as heat resistance and flexibility, which can impact the molding process. For instance, using a high-temperature resistant resin can be beneficial when working with materials that require elevated curing temperatures. Therefore, selecting a material that aligns with the specific requirements of the resin molding process is paramount.

In conclusion, creating effective 3D printed masters for resin molding involves a multifaceted approach that encompasses technology selection, design considerations, print optimization, post-processing, and material choice. By adhering to these best practices, manufacturers can ensure that their masters not only meet the desired specifications but also contribute to the overall quality and efficiency of the resin molding process. As 3D printing technology continues to evolve, staying informed about advancements and techniques will further enhance the capabilities of this innovative manufacturing method.

Common Challenges and Solutions in Resin Molding with 3D Printed Masters

The integration of 3D printed masters in resin molding has revolutionized the manufacturing landscape, offering unprecedented precision and customization. However, this innovative approach is not without its challenges. Understanding these common obstacles and their corresponding solutions is essential for achieving optimal results in resin molding.

One of the primary challenges encountered when using 3D printed masters is the dimensional accuracy of the printed parts. While 3D printing technology has advanced significantly, variations in printer calibration, material shrinkage, and environmental factors can lead to discrepancies between the printed master and the final molded product. To mitigate this issue, it is crucial to conduct thorough calibration of the 3D printer before production begins. Regular maintenance and adjustments can help ensure that the printer consistently produces accurate dimensions. Additionally, utilizing high-quality printing materials that have minimal shrinkage can further enhance the fidelity of the master.

Another common challenge is the surface finish of the 3D printed master. Often, the layer lines and texture inherent in 3D printing can transfer to the resin mold, resulting in a less-than-desirable finish on the final product. To address this, several techniques can be employed. Post-processing methods such as sanding, polishing, or applying a primer can significantly improve the surface quality of the master. Furthermore, using a resin that has a high gloss finish can help mask minor imperfections, leading to a smoother final product.

In addition to surface finish, the choice of resin itself presents another challenge. Different resins have varying properties, including viscosity, cure time, and flexibility, which can affect the molding process. For instance, a resin that cures too quickly may not allow for adequate air release, leading to trapped bubbles and defects in the final product. To overcome this, it is advisable to conduct preliminary tests with different resin formulations to identify the most suitable option for the specific application. Additionally, incorporating additives that enhance flow or reduce viscosity can improve the overall quality of the mold.

Moreover, the complexity of the design can pose significant challenges during the molding process. Intricate geometries may lead to difficulties in mold release or result in areas that are prone to defects. To counteract this, it is essential to design the master with mold-making principles in mind. This includes incorporating draft angles to facilitate easier removal from the mold and ensuring that there are no undercuts that could complicate the demolding process. Collaborating with experienced mold makers can also provide valuable insights into design modifications that enhance manufacturability.

Lastly, the environmental conditions during the molding process can greatly influence the outcome. Factors such as temperature and humidity can affect the curing of the resin, leading to inconsistencies in the final product. To ensure optimal curing conditions, it is advisable to maintain a controlled environment where temperature and humidity levels are monitored and regulated. This not only enhances the quality of the mold but also contributes to the overall efficiency of the production process.

In conclusion, while the use of 3D printed masters in resin molding presents several challenges, understanding these obstacles and implementing effective solutions can lead to successful outcomes. By focusing on dimensional accuracy, surface finish, resin selection, design considerations, and environmental control, manufacturers can harness the full potential of this innovative technology, ultimately resulting in high-quality molded products that meet the demands of various applications.

Q&A

1. **Question:** What are the advantages of using 3D printed masters for resin molding?

**Answer:** 3D printed masters allow for rapid prototyping, precise detail, and customization, reducing lead times and costs compared to traditional master-making methods.

2. **Question:** What materials are commonly used for 3D printing masters intended for resin molding?

**Answer:** Common materials include PLA, ABS, and resin, with resin printers often providing higher detail and smoother finishes suitable for molding.

3. **Question:** How do you prepare a 3D printed master for resin molding?

**Answer:** The master should be cleaned, sanded to remove imperfections, and possibly coated with a release agent to ensure easy demolding and prevent adhesion of the resin.Using 3D printed masters in resin molding offers significant advantages, including enhanced design flexibility, reduced production time, and cost efficiency. The precision of 3D printing allows for intricate details and complex geometries that traditional methods may struggle to achieve. Additionally, the ability to quickly iterate designs and produce small batches makes it an ideal solution for prototyping and custom applications. Overall, this approach streamlines the manufacturing process while maintaining high-quality standards, making it a valuable technique in various industries.